Tuff Torq Oil Service Procedure for Strider™ units with Internal Reservoir Tank

Models covered by this procedure:

- Strider™

- Manufacturing ID: K46AA, K46AC, K46AG K46AW, K46BA, K46BC, K46BE, K46BL, K46BM, K46BN, K46BP, K46BR, K46BT, K46C, K46CJ, K4CR, K46CW, K46HD, K46V, K46Z

- Strider™ HD

- Manufacturing ID: K57A & K57F

- T40A & T40J

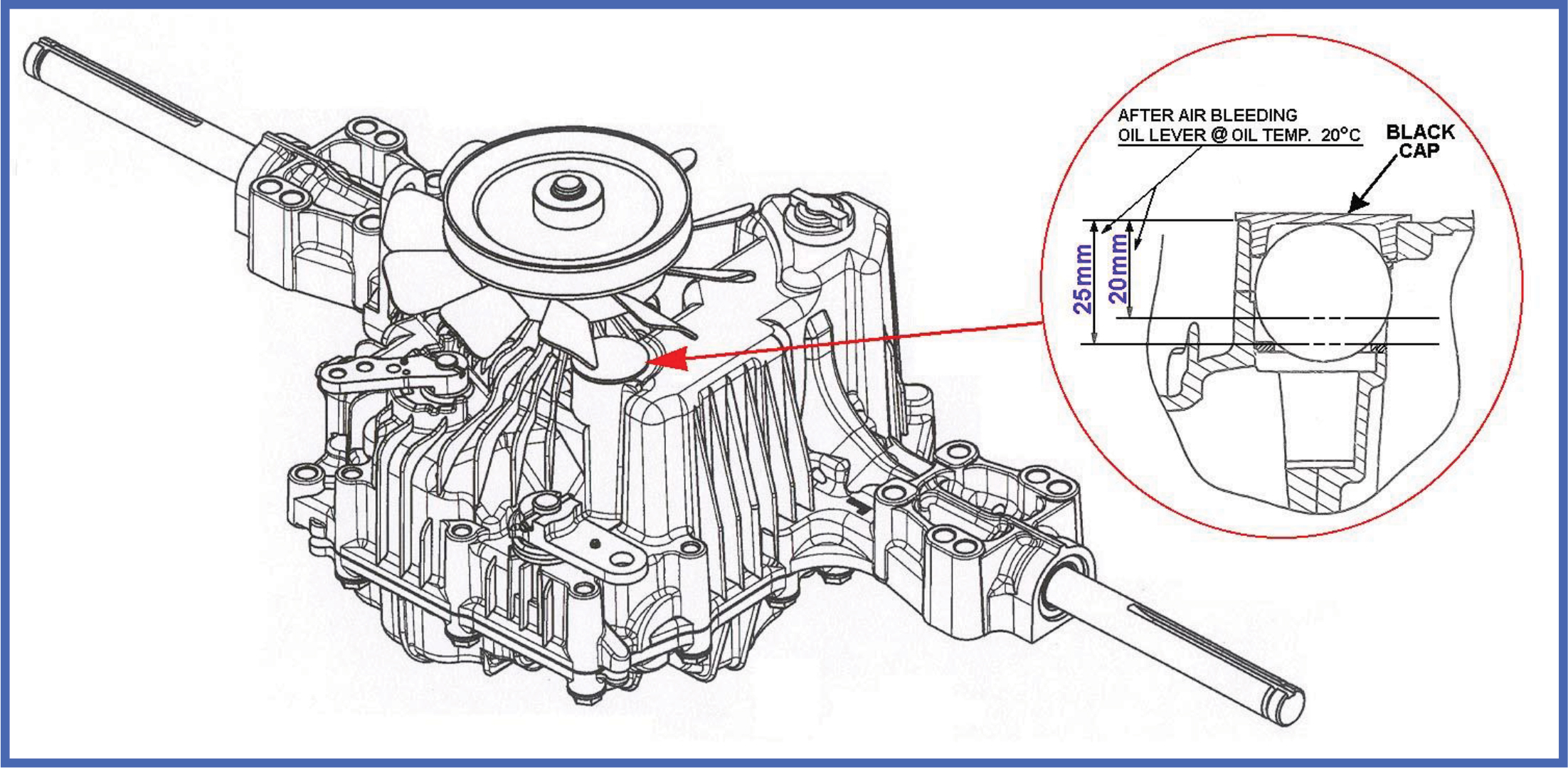

Normally the model K46 & T40A transaxles, that are featured in many tractor and rider models, do not require any servicing for the life of the vehicle. If checking the oil level/condition, it may be necessary to remove the transaxle from the vehicle. This is necessary to access the fill port (black cap) located under the pulley and fan (see diagram below).

After removing the unit from the vehicle, place the transaxle on a level surface and remove the fan and pulley. Then remove the black cap shown in the diagram below. Maintain the oil level at 20~25 mm (3/4”~1”) below the lip of (black cap) port (see diagram below).

Technical note: Check oil level when oil is at room temperature (20°C or 68° F) and the unit case is level and secure.

Always use the fill port (under the black cap) to drain the oil from your Tuff Torq unit. Do this by removing the cap and inverting transaxle.

Tuff Torq recommends using only using approved Tuff Tech™ drive fluid when servicing any of our transaxles. Only use the fill port (covered by the black cap) to refill unit. You will need approximately 2.2 liters of oil to properly refill the unit if completely empty. The amount of oil needed may vary for your service, due to the amount of residual oil remaining in case after draining and the condition/age of the unit you are servicing.

While reinstalling the fan & pulley be sure to place all components on the drive shaft in the reverse order from which they were removed and verify proper torque for each bolt.

Tuff Torq Oil Service Procecdure Diagram