Tips for Tuff Torq Repair Kits

(K46, K57, K574, T40 MODELS)

The Tuff Torq service team has put together this summary outline procedure for using our Tuff Torq repair kits to service your drive system. These are just tips and should not be considered a complete repair guide for every issue you might have. All repairs and maintenance of our drive systems should be performed by a professional service technician. If you have any questions or need specific help for your issue, feel free to contact our service team at (866) 572-3441 or through the website by clicking here.

Receive the correct repair kit

- First, clean the outside debris from the unit.

- Be sure to locate the proper serial number of the TTC unit (Located on the barcode sticker).

Removing unit for repair

- After you have received your parts, please inspect the parts. Note the mating surfaces must be smooth and clean.

- Repair Kits generally include the center case, pump cylinder block, motor cylinder block, filter, o-rings, seals, and sealant. When repairing your unit, it may not be necessary to use all o-rings, and seals.

- Drain the oil from the unit. (DO NOT reuse the oil) Remove the flat rubber seal cap located under the fan to drain the oil. No need to remove the vent valve.

- Place the unit on your workbench with the fan facing down.

Opening unit an performing repair

- Remove the case bolts and remove the lower housing.

- Scrape the sealant from both the upper and lower cover. Be careful not to damage the sealing surface while scraping the housings. (Remove all sealant completely)

- Now is the time to use the drawing and parts list from TTC’s website to identify everything inside the unit www.tufftorqservices.com.

- Clean and flush the unit. Improper cleaning of the unit could result in a premature failure or void the parts warranty. You can clean internal parts with standard brake cleaner.

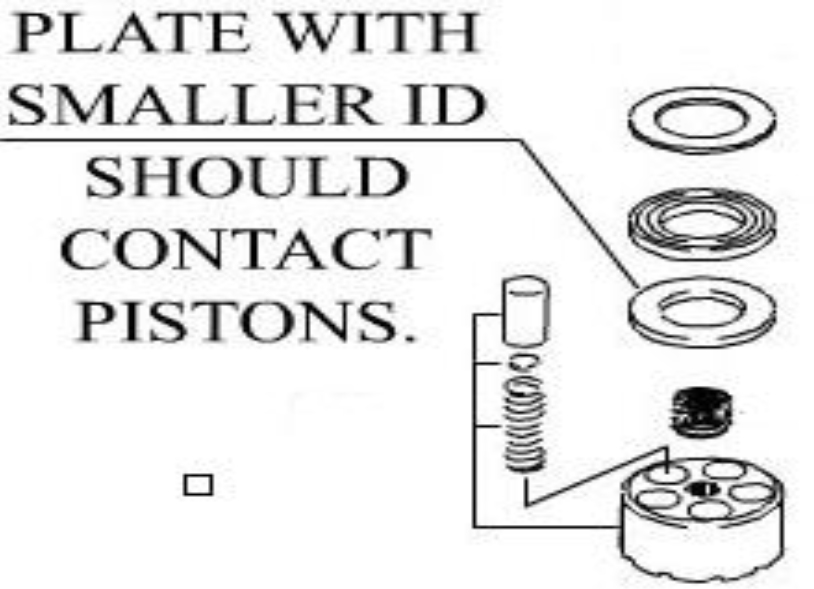

- If you choose to inspect any parts make sure these parts are placed back into the proper orientation. (Ex. If you remove a bearing or a plate make sure that it is placed back into the proper position. Plate with smaller ID (INSIDE DIAMETER) should contact Pistons.) The notes are listed on most drawings so be sure to follow these tips properly. (see Fig#1)

Using Tuff Torq repair kits – Figure 1

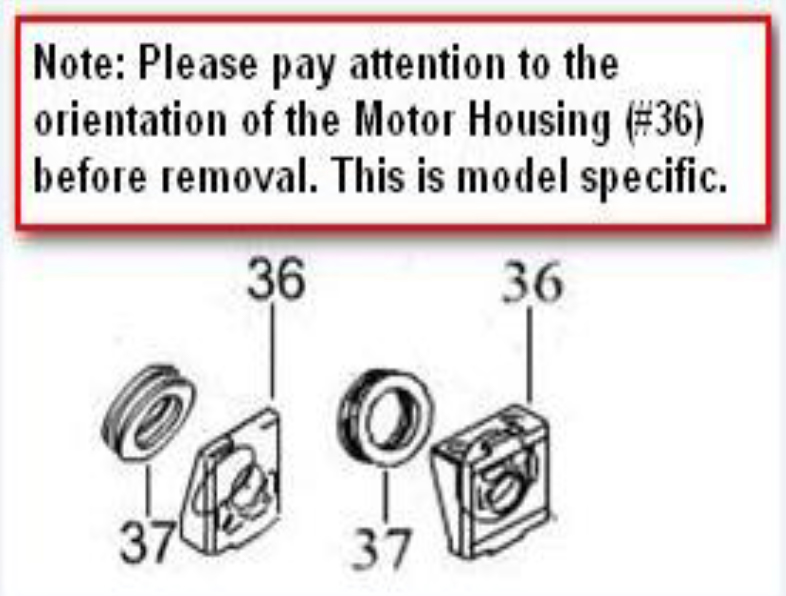

- Note the original position of the Motor Housing. (see Fig.#2)

Using Tuff Torq repair kits – Figure 2

- Once you are ready to install the parts be sure to coat the mating surfaces with oil. This will help lubricate the contact surfaces.

Re-assembly of unit

- Make sure to re-install the bypass pin and washer from the original center case and motor cylinder block. You can use a light amount of automotive grease or Vaseline to keep these two parts in position while putting the parts back in.

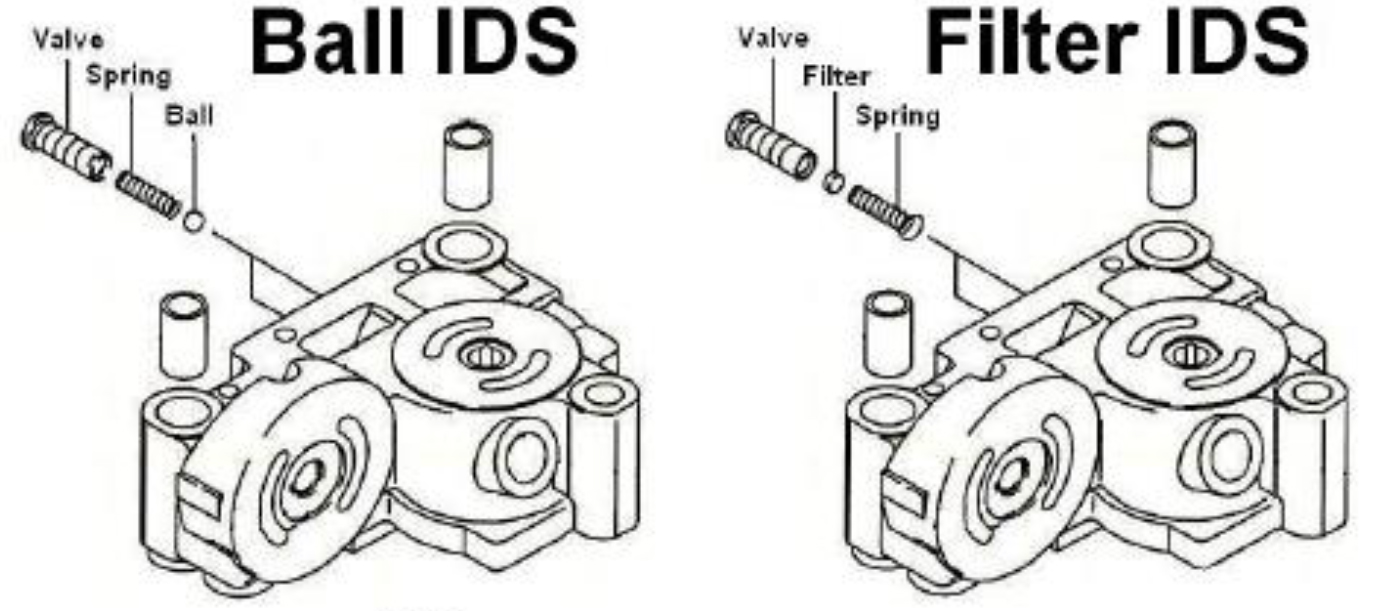

- If the unit has IDS valves, be sure to note the correct position of the ball or the filter compared to the drawing (see Fig.#3).

Using Tuff Torq repair kits – Figure 3

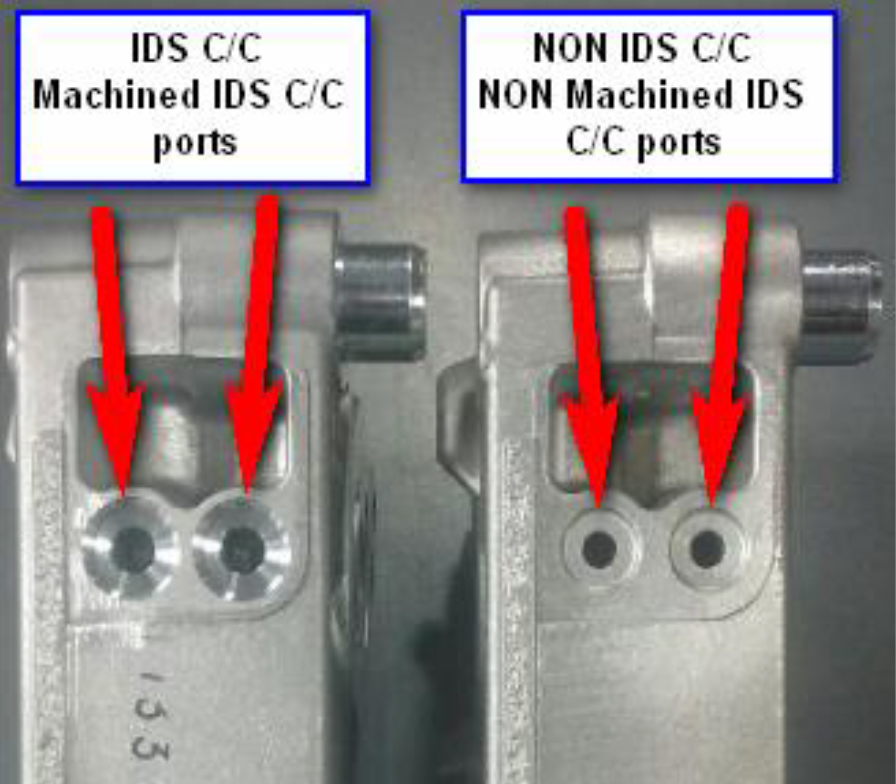

- New center cases will have pilot holes for the IDS system. See figure 4 to understand the difference between IDS and non-IDS units. The non-IDS unit will not have finished machining at the pilot holes. This is simply in the case mold design of the new center-case and does not impact the performance of your unit.

Using Tuff Torq repair kits – Figure 4

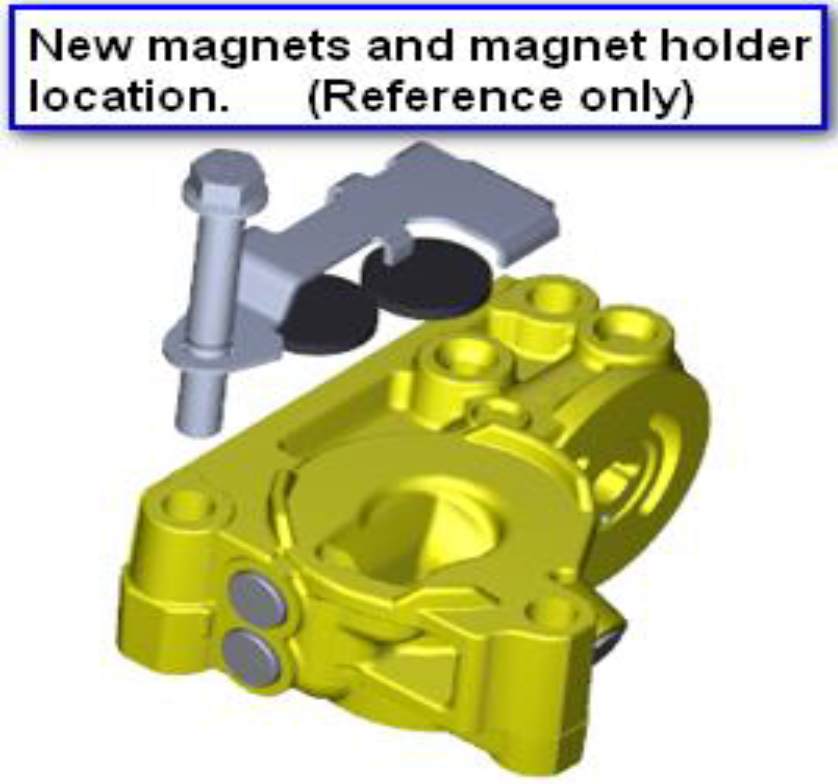

- New style magnet holder and two magnets (see Fig.#5 on back) for proper orientation.

Using Tuff Torq repair kits – Figure 5

- After re-installation, check to see if everything will rotate freely.

- It is critical that the operator maintains proper oil levels at all times.

- Maintain oil level at 20~25 mm (3/4”~1”) below the lip of (black cap) the filling port.

- Always check oil level when the oil temperature is at room temperature (20C or 68 F).

- When replacing oil in your unit, Tuff Torq Corporation recommends using Tuff Torq Tuff Tech™ hydrostatic drive fluid when rebuilding Tuff Torq transaxles. (DO NOT use ATF Automatic Trans Fluid)